Comparing Foam Types: Why Polyurethane Foam Stands Out for Commercial Use

Why does polyurethane foam stand out for commercial use?

- Offers excellent thermal insulation

- Can expand and fill irregular spaces

- Resists acids, bases, and solvents

- Can be manufactured with flame-retardant additives

- Has customizable properties

- Has a high-strength-to-weight ratio

Overview

- Polyurethane foam offers a unique combination of versatility, thermal efficiency, and chemical resistance, making it ideal for various industrial and commercial applications.

- Its self-expanding nature and customizable properties allow precise fitting and tailored performance across sectors like construction, automotive, and packaging.

- For reliable, high-quality polyurethane foam solutions, businesses trust Uratex, a leading supplier in the Philippines for over 55 years.

Commercial operations depend on materials that deliver durability, comfort, and cost-efficiency under heavy use. Choosing the wrong foam can lead to frequent replacements, inconsistent performance, and higher operational costs.

In this article, we explore the differences among common foam types and highlight their strengths and weaknesses. We also explain why polyurethane foam stands out for commercial use, offering the durability, resilience, and consistent quality businesses need. By understanding these differences, procurement and engineering teams can make informed decisions that optimize both performance and long-term value.

Keep reading to learn more!

Foam Types, Their Key Properties and Uses

Different foam types bring unique characteristics designed to meet specific commercial and industrial needs. By understanding how each material performs in terms of durability, flexibility, insulation, and resistance, businesses can make informed choices for their applications.

The table below highlights the key properties and typical uses of commonly used foams:

|

Foam Type |

Key Properties |

Common Uses |

|

Polyurethane (PU) |

Adaptable, budget-friendly, available in various densities and firmness levels |

|

|

Memory Foam |

Viscoelastic, conforms to body shape, provides pressure relief |

|

|

Latex Foam |

Bouncy, buoyant, durable, natural option, often more expensive |

|

|

Polystyrene (EPS) |

Rigid, lightweight, good thermal insulation |

|

|

Polyethylene (PE) |

Flexible, lightweight, water-resistant, good shock absorption |

|

|

Polypropylene (EPP) |

Durable, reusable, flexible |

|

With these options in mind, it’s clear that while each foam type has its advantages, polyurethane foam consistently offers the best balance of adaptability, durability, and cost-effectiveness for commercial applications. Its ability to meet diverse operational demands while maintaining performance makes it the preferred choice for businesses across industries. This is why polyurethane foam stands out for commercial use.

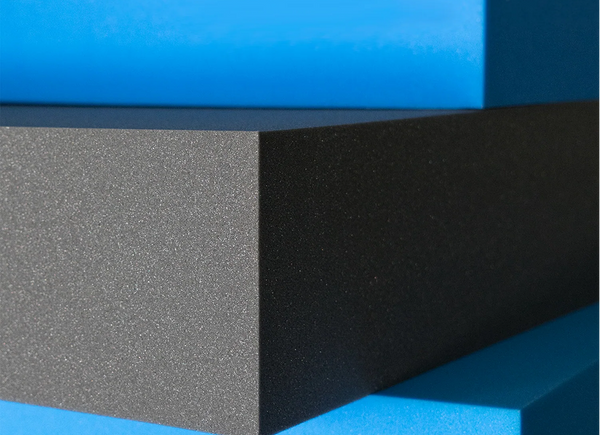

Offers Excellent Thermal Insulation

Commercial-grade PU stands out for its ability to reduce heat transfer, helping environments stay warm or cool while cutting energy use. Its closed-cell structure traps millions of tiny gas pockets, creating a highly efficient insulating layer that many other foams, like memory or latex foam, cannot match. This makes it ideal for construction applications such as wall and roof insulation, refrigeration units, and automotive interiors.

Businesses benefit from improved thermal efficiency and long-term energy savings compared with alternatives that provide weaker or uneven insulation.

Has the Ability to Expand and Fill Irregular Spaces

High-performance foam starts as a liquid that quickly reacts and expands, filling gaps, cracks, and uneven areas with precision.

Unlike rigid or pre-shaped foams, this self-expanding property ensures complete coverage and a tight seal. It’s particularly useful in construction, packaging, and manufacturing, where uniform insulation, cushioning, or bonding is essential. The result is better performance, minimized material waste, and a more efficient production process.

Resistant to Acids, Bases, and Solvents

PU’s tightly cross-linked polymer structure gives it exceptional resistance to acids, bases, and industrial solvents, maintaining shape and strength even in harsh environments.

Other common foams, such as polystyrene or polyethylene, may degrade or soften under similar exposure. This durability makes it reliable for demanding settings like manufacturing facilities, laboratories, and chemical storage areas, ensuring long-lasting performance and safety.

Can Be Manufactured With Flame-Retardant Additives

Commercial PU can be manufactured with fire-resistant additives such as halogenated compounds, phosphates, or melamine-based agents. These formulations slow ignition and reduce heat release, enhancing safety in environments where flammability is a concern.

Compared with other foams like memory or latex, which often require additional treatments for fire resistance, this inherent capability makes PU a preferred choice in construction, transportation, and furniture applications.

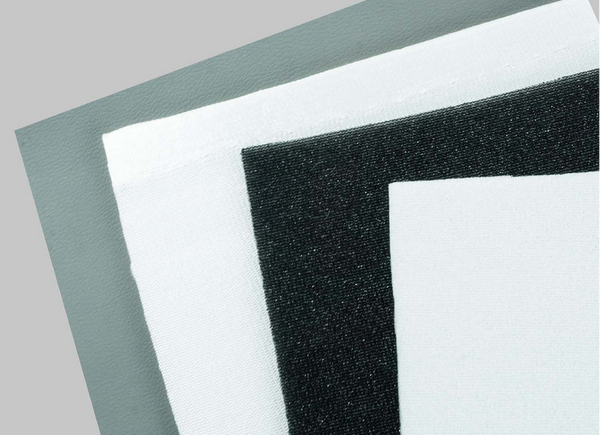

Customizable Properties

By adjusting the ratios of polyols, diisocyanates, and blowing agents, manufacturers can fine-tune density, firmness, and flexibility. This precision affects how the material responds to pressure, provides support, and handles environmental stresses.

Such adaptability allows businesses—from automotive to healthcare—to access foam solutions tailored to their technical and operational needs. This versatility enables them to outperform many less flexible foam types.

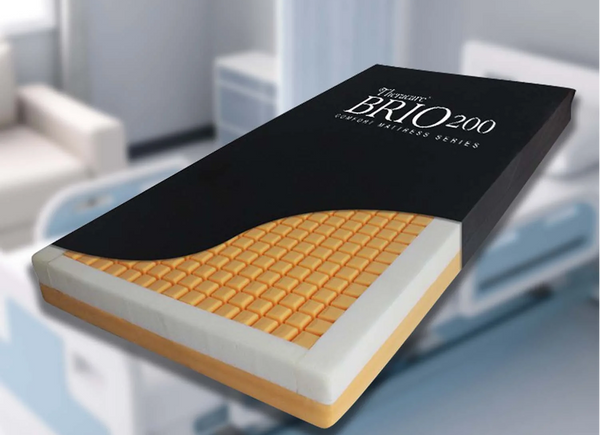

Has a High-Strength-To-Weight Ratio

Thanks to its cellular structure, PU maintains strong mechanical performance while remaining lightweight. This combination allows it to withstand repeated compression, impacts, and heavy use without adding unnecessary bulk.

Other foams, such as EPS or PE, may be either lighter but less durable or stronger but heavier. The superior strength-to-weight balance makes it ideal for vehicles, insulation panels, and packaging where both performance and efficiency are critical.

Get Reliable Polyurethane Foam From Uratex Today!

When your business requires foam that combines durability, flexibility, and consistent performance, partnering with the right supplier is crucial. For over 55 years, Uratex has been a trusted provider of high-quality PU foam in the Philippines. We serve industries from construction and automotive to furniture and packaging.

Our materials are engineered for precision, resilience, and long-term performance, ensuring that every application—from insulation panels to vehicle interiors—meets both local and international standards.

By choosing Uratex, companies gain a reliable partner that understands the unique requirements of commercial applications and provides solutions that truly stand the test of time.

Key Takeaway

Why polyurethane foam stands out for commercial use is clear: its versatility, durability, and ability to meet the demands of various industries. Its distinct combination of resilience, personalization, and performance makes it the perfect choice for companies seeking trusted and efficient material solutions.

For dependable polyurethane foam solutions in the Philippines, turn to Uratex. With over 55 years of experience, Uratex delivers high-grade foam tailored for commercial uses.

Contact us today to discuss bulk orders, product specifications, or custom solutions for your business requirements.