Signs Your Business Needs a More Reliable Foam Supplier in the Philippines

What are the signs your business needs a more reliable foam supplier in the Philippines?

- Frequent late deliveries

- Inconsistent quality and order inaccuracies

- Communication and transparency problems

- Lack of capacity

- Lack of flexibility

- Financial instability

- Poor track record

- High hidden costs

Overview

- Production delays, inconsistent foam quality, and poor communication frequently disrupt manufacturing workflows, leading to costly schedule adjustments and inefficiencies.

- These challenges cause teams to spend extra time correcting mistakes, impacting product output and customer satisfaction.

- Uratex offers reliable, high-quality polyurethane foam with on-time deliveries and transparent communication, making it a dependable partner that supports seamless production in the Philippines.

High-quality foam plays a critical role in ensuring product safety, performance, and industry compliance—yet not all suppliers consistently meet these standards. When durability tests fail or materials arrive out of spec, it can jeopardize entire production lines and put your business at risk. These issues often appear long before managers realize they stem from the supplier, making it essential to recognize the signs that your business needs more reliable foam suppliers in the Philippines.

Procurement teams, product engineers, and operations managers all rely on dependable materials to maintain quality control and meet regulatory requirements. When a supplier can’t uphold consistency, certification, or traceability, the consequences ripple across every stage of manufacturing.

This article outlines the early warning signs to help you determine when it’s time to upgrade to a more trustworthy foam partner.

Frequent Late Deliveries

Consistent delays in deliveries are one of the clearest signs that your current foam provider can’t support your operational needs. When shipments arrive late, production lines are forced to slow down or pause entirely, affecting output and delivery commitments. These setbacks often stem from poor inventory control, weak logistics processes, or inadequate coordination on the supplier’s end.

As a result, teams may need to reshuffle resources or place emergency orders just to stay on schedule. This adds stress, unexpected costs, and avoidable workflow disruptions.

Inconsistent Quality and Order Inaccuracies

Another red flag is receiving foam materials that don’t match the agreed specifications. This can be either in density, thickness, cut size, or finish. These issues usually point to weak quality assurance systems or rushed manufacturing processes on the part of the foam producer.

When materials fall short of standards, assembly slows down, rework increases, and customer-facing products risk failing performance tests. Engineers and production teams also end up spending more time validating every batch instead of focusing on efficiency and output.

Communication and Transparency Problems

A dependable manufacturing partner keeps you informed, especially when timelines or specifications change. If your current foam distributor fails to provide timely updates or clear explanations, it becomes difficult for procurement, engineering, and operations teams to plan effectively.

Lack of visibility around delivery schedules or stock availability creates unnecessary uncertainty and raises the likelihood of costly errors. Over time, poor communication signals that the supplier may not have the systems or commitment to support growing business requirements.

Lack of Capacity

A reliable materials partner should be able to support both routine orders and sudden increases in demand. When a foam manufacturer consistently struggles to fulfill bulk or urgent requests due to limited production lines, storage constraints, or weak logistics, it becomes a clear sign that they can’t scale with your business. These bottlenecks often cause partial deliveries, extended lead times, and last-minute scrambling for backup sources.

Over time, limited capacity disrupts production flow and restricts your ability to meet client commitments with confidence.

Lack of Flexibility

In fast-moving industries, procurement and engineering teams need a materials provider that can adjust to shifting requirements. If your current foam producer cannot accommodate changes in quantity, specifications, or delivery schedules, the lack of adaptability becomes a serious operational hurdle. This rigidity forces businesses to work around constraints that should have been easily managed with a more agile partner.

The result is slower turnaround times, unnecessary waste, or missed opportunities. It ultimately affects your ability to innovate or respond to market needs.

Financial Instability

Suppliers facing financial challenges often display warning signs such as delayed payouts to subcontractors, inconsistent material quality, or repeated failure to meet delivery promises. These issues can quickly jeopardize your production schedule and create uncertainty in both planning and budgeting.

Financially unstable vendors may suddenly run out of stock, downgrade components, or halt orders altogether. For procurement and operations teams, this means urgent contingency sourcing, higher costs, and increased risk to overall business continuity.

Poor Track Record

A material partner’s reliability is often reflected in the experiences of those who have worked with them before. When previous clients consistently note issues such as late shipments, inconsistent output, or incomplete orders, it signals deeper operational weaknesses. These patterns can easily spill over into your own production line, causing delays and unnecessary bottlenecks.

Sticking with a provider that has a history of performance problems often results in repeated disruptions and constant firefighting. This makes it challenging to maintain smooth operations and uphold the quality standards your business is aiming for.

High Hidden Costs

Some foam distributors may seem cost-effective at first glance, only for unexpected charges—like rush fees, rework costs, or special handling add-ons—to surface later. These unplanned expenses gradually cut into budgets and reduce the efficiency you initially expected.

When surprise costs become frequent, it becomes harder for procurement teams to forecast spending or optimize purchasing strategies. Over time, these financial inconsistencies can outweigh any upfront savings and complicate both operational and long-term planning.

Choose Uratex, Your More Reliable Polyurethane Foam Supplier in the Philippines

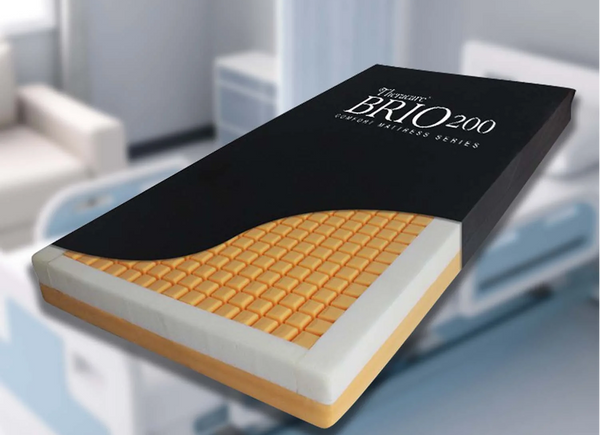

When you work with Uratex, you eliminate the usual headaches—late deliveries, fluctuating quality, unexpected charges, and suppliers who are hard to reach. Our long-standing track record means your foam requirements are delivered on schedule, complete, and aligned with your exact specifications. This helps your production lines run smoothly without costly interruptions.

Our polyurethane foam is engineered for precision, durability, and consistent performance. By using premium polyols and isocyanates, advanced formulations, and rigorous quality assurance, we produce foam that meets the strict demands of industries that prioritize comfort, resilience, and long-term reliability.

With Uratex as your manufacturing partner, you get materials you can trust—batch after batch.

Key Takeaway

Knowing the signs your business needs a more reliable foam supplier in the Philippines early can save time, reduce costs, and prevent operational disruptions. Whether it’s late deliveries or inconsistent quality, understanding these red flags helps procurement officers act before production and efficiency are sacrificed.

Working with Uratex ensures a smooth, dependable supply of high-quality polyurethane foam for your business. With decades of experience, technical expertise, and a commitment to consistency, we support your operations, whatever industry you belong to.

Contact us today to learn more about bulk orders, custom specifications, and how we can help streamline your supply chain.