7 Industries That Use Polyurethane Foam

What are the industries that use polyurethane foam?

- Building and construction

- Automotive

- Furniture and furnishing

- Footwear

- Packaging

- Electronics

Overview

- Polyurethane foam offers versatile solutions across industries like construction, automotive, and healthcare by providing thermal insulation, cushioning, and impact absorption.

- Its lightweight and durable properties improve energy efficiency, comfort, and safety in various applications.

- For reliable bulk supply, Uratex stands out in the Philippines, known for over 50 years of quality and innovation in polyurethane foam products.

Businesses need materials that deliver durability, comfort, and protection while meeting strict industry standards. Polyurethane foam meets these demands, making it a versatile solution for many operational and manufacturing challenges.

In this article, we explore the industries that use polyurethane foam and how each leverages its unique properties to enhance performance, efficiency, and product quality. From cushioning and insulation to structural support and safety, PU foam provides measurable value across diverse sectors.

Understanding these applications helps procurement managers and product engineers make informed decisions when selecting materials for their operations.

Building and Construction

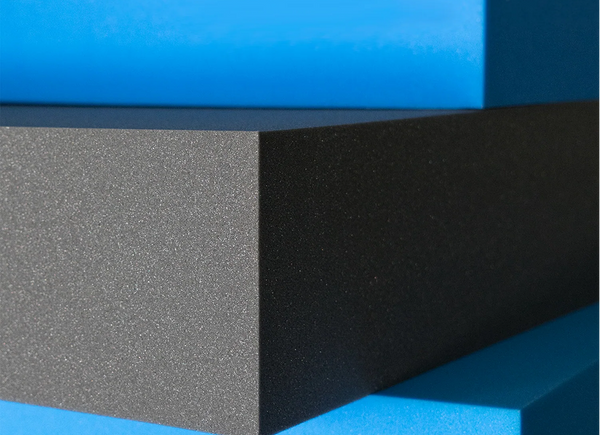

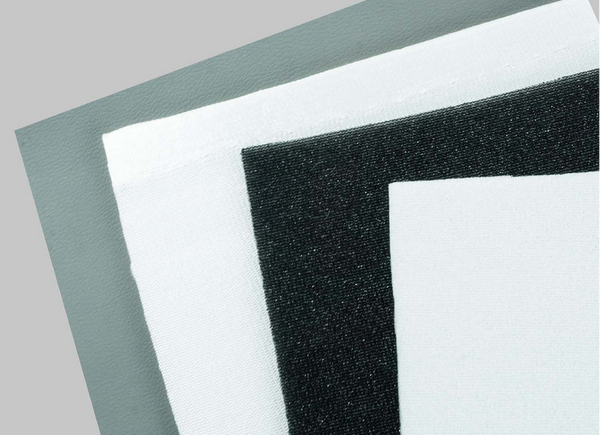

The construction sector increasingly demands materials that improve energy efficiency, comfort, and long-term durability. PU foam is lightweight yet strong, making it ideal for insulation, air sealing, and soundproofing.

In walls, roofs, and foundations, its thermal resistance and moisture-blocking properties help maintain consistent indoor temperatures. It also reinforces structural stability and reduces energy loss, supporting both commercial and residential projects in achieving cost-effective climate control.

Automotive

Vehicle manufacturers prioritize materials that enhance passenger comfort, safety, and overall performance. Engineered foam is used in car seats, headrests, armrests, ceiling liners, and interior panels to provide cushioning and absorb impacts. Its shock-absorbing properties help reduce injury during collisions, while its vibration-dampening ability improves ride quality.

Lightweight yet durable, it contributes to fuel efficiency without compromising cabin design or longevity.

Furniture and Furnishing

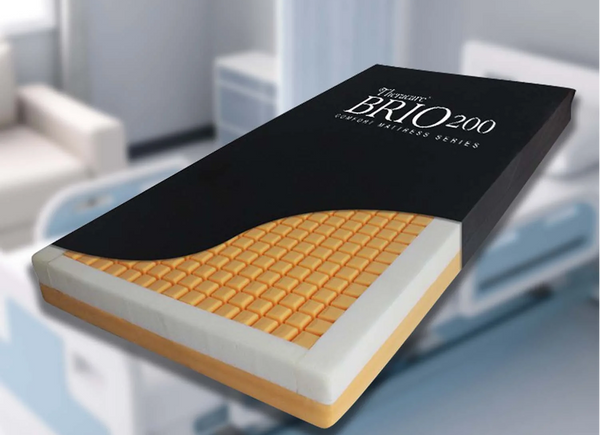

Comfort and durability are paramount in furniture design. Foam cushioning plays a central role in sofas, chairs, mattresses, and other upholstered products, with firmness or softness tailored to the intended use. The material adapts to the body while retaining shape, keeping furniture supportive over the years of use.

Its versatility also enables manufacturers to optimize material usage, minimize waste, and maintain consistent product quality.

Footwear

Shoes require materials that provide reliable support, shock absorption, and flexibility for everyday and athletic activities. Flexible foam is commonly used in midsoles, insoles, and padding for sneakers, boots, and casual footwear. Its lightweight construction reduces foot fatigue while stabilizing the stride, delivering comfort and durability for prolonged wear.

Packaging

Protecting fragile or high-value products is critical during transport and storage. PU inserts and molded foam layers safeguard electronics, instruments, and delicate goods by absorbing shocks and resisting compression. This adaptable cushioning minimizes material waste while ensuring items remain intact, even under heavy stacking or rough handling conditions.

Electronics

Electronic devices demand protective materials that maintain integrity without adding bulk. Foam materials are widely used for device housings, packaging, and thermal insulation in appliances and circuit boards.

Cushioning, temperature regulation, and anti-static properties prevent damage from shocks or environmental changes, helping manufacturers ensure consistent product performance.

Key Benefits of PU Foam Across Industries

Across sectors, polyurethane foam proves invaluable for its combination of performance, adaptability, and reliability. Its unique properties allow businesses to enhance product quality, improve efficiency, and meet operational demands.

Some of the key benefits include:

- Versatility: Can be customized for cushioning, insulation, impact absorption, or structural support.

- Durability: Retains shape, resists wear and tear, and supports long-term use.

- Lightweight & Efficient: Reduces weight in vehicles, furniture, or packaging, improving energy efficiency and handling.

- Comfort & Safety: Offers ergonomic support in furniture, footwear, and healthcare products while enhancing protection.

- Cost-effectiveness: Optimizes material use, reduces replacements, and minimizes waste.

Where to Get Polyurethane Foam in Bulk Based on Your Industry Needs?

For businesses seeking reliable bulk foam solutions, Uratex has been a leading supplier in the Philippines for over 50 years. We provide tailored options across industries—from automotive and healthcare to furniture and packaging—ensuring each product meets specific operational requirements.

Our commitment to quality, consistency, and innovation means every batch is engineered for durability, resilience, and optimal performance. Partnering with us at Uratex allows companies to enhance efficiency, product value, and reliability across all applications.

Key Takeaway

Understanding the various industries that use polyurethane foam emphasizes its versatility and key role in enhancing comfort, performance, and efficiency across sectors. By noticing how this material solves industry-specific challenges, businesses can make smarter, more informed decisions when choosing foam solutions.

For reliable, top-quality polyurethane foam tailored to your industry needs, Uratex makes it easier for you. Reach out to us today to discuss bulk orders, custom solutions, or to request a consultation.