Common Upholstery Problems in the Furniture Sector

Overview

- Inconsistent upholstery quality leads to customer dissatisfaction and increased production costs in furniture manufacturing.

- Addressing material durability and environmental stressors early ensures long-term product performance and user comfort.

- Uratex provides high-resilience polyurethane foam solutions that enhance consistency, reduce rework, and support efficient, scalable upholstery operations.

Faulty or low-quality upholstery can quickly escalate costs through rework, replacements, and warranty claims. Identifying the common upholstery problems in the furniture sector helps operations and procurement teams make smarter choices about materials, vendors, and production methods.

Frequent issues such as sagging cushions, torn fabrics, or seam failures can disrupt manufacturing and inflate budgets if not addressed early. By understanding these recurring challenges, businesses can protect profitability and ensure consistent product quality. Having the right type of foam might be the key you need—keep reading to learn more.

Fabric and Surface Issues

Visible fabric problems are often the first signs that upholstery is underperforming. These surface imperfections don’t just affect appearance, but they can also indicate deeper issues with the underlying foam, fabric tension, or adhesion quality.

Addressing them early helps maintain both comfort and durability, preventing costly rework or replacements.

Fading and Discoloration

Fading occurs when fabrics lose their original color, showing uneven tones, patchy bleaching, or a dull finish. Factors such as UV exposure, humidity, and harsh cleaning agents can break down dyes over time.

In some cases, the foam beneath may also discolor due to oxidation or moisture, signaling early material wear that can compromise comfort and support.

Pilling and Fiber Buildup

Pilling happens when tiny fiber balls form on the fabric surface from friction or abrasion. High-use areas, where fabric stretches or pulls, accelerate this process.

Over time, pilling not only affects appearance but can also weaken the fabric’s structure and reduce the foam’s cushioning effectiveness.

Wrinkles and Comfort Creases

Wrinkles appear when fabric loosens from its original taut state, while deeper comfort creases form in areas where foam and fabric repeatedly compress. These changes can result from continuous use, temperature shifts, or underlying foam fatigue.

Left unchecked, they indicate declining material resilience and may reduce overall seating comfort.

Stains and Deterioration

Stains occur when liquids or oils penetrate the fabric fibers, leaving discoloration or residue that’s hard to remove. Deterioration refers to the gradual breakdown of both fabric and underlying foam due to moisture, microbial growth, or chemical reactions from cleaning agents.

As foam loses structural support, sagging, odors, and reduced comfort often follow.

Tears and Scratches

Tears and scratches arise from mechanical stress, rough handling, or transport issues. Small surface abrasions can expand over time, exposing the foam to dust and moisture. This accelerates deterioration and reduces the furniture’s lifespan, emphasizing the need for durable materials and proper maintenance.

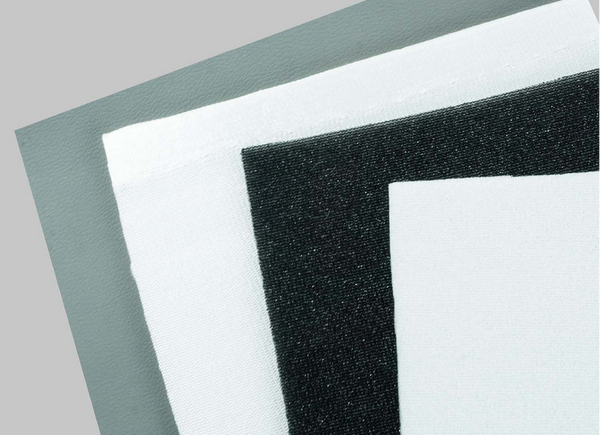

Structural and Cushioning Problems

Beyond surface wear, furniture performance depends heavily on its internal structure and cushioning materials. Weak frames, low-quality foam, or uneven weight distribution can cause cushions to lose shape and compromise overall comfort.

These structural issues not only reduce user satisfaction but also accelerate material fatigue, leading to higher replacement and maintenance costs.

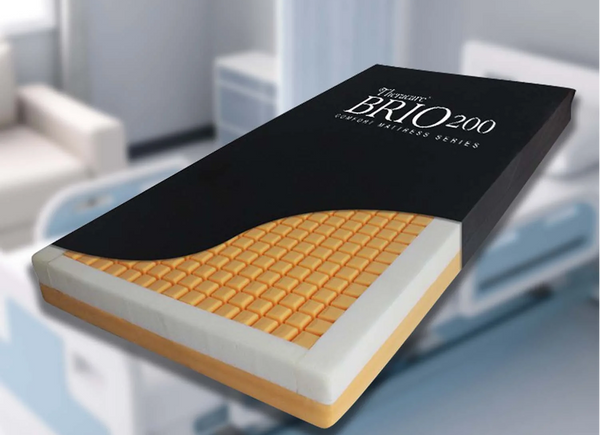

Sagging Cushions

Cushions begin to sag when the foam inside loses resilience or compresses unevenly over time. This creates an uneven seating surface that fails to provide proper support, affecting posture and comfort.

In more severe cases, sagging can place extra strain on the furniture frame, wearing down joints and potentially causing premature structural failure.

Poor Support Structure

When the underlying frame, springs, or webbing cannot distribute weight evenly or maintain shape, furniture stability suffers. Wobbly seating, uneven surfaces, and accelerated foam compression become common issues.

Over time, these weaknesses reduce comfort, reliability, and the overall lifespan of the piece, emphasizing the importance of both quality materials and sound construction.

Factors Contributing to Problems

Several factors influence the durability and performance of upholstered furniture. Understanding these helps companies identify root causes and choose better materials and designs.

- Low-Density Foam & Weak Fabric – Cushions lose shape quickly; fabric frays or stretches.

- High Humidity & Heat – Accelerates foam breakdown; fabrics warp, fade, or mildew.

- Heavy or Frequent Use – Constant sitting and shifting compress cushions and stretch coverings.

- Harsh Chemicals & Improper Cleaning – Solvents, bleach, or rough scrubbing degrade fibers and foam.

How Uratex Streamlines Upholstery Production

Uratex provides premium foam engineered to enhance efficiency and reliability in furniture manufacturing. With over 55 years of experience in the Philippines, we deliver materials with consistent density, durability, and customizable properties, helping manufacturers create furniture that stays comfortable and long-lasting.

By offering dependable, high-performance foam, we help reduce production errors, improve quality control, and support smooth workflows. Combined with timely delivery and expert technical guidance, Uratex becomes a trusted partner for businesses seeking operational consistency and superior end products.

Key Takeaway

Addressing common upholstery problems in the furniture sector is key for manufacturers looking for consistent quality, comfort, and durability in their products. Noticing issues like sagging cushions, fabric deterioration, and unjust support helps organizations make informed decisions about products and production methods.

Uratex delivers top-grade polyurethane foam that ensures reliability, resilience, and uniformity across all furniture pieces. With decades of experience in supplying, we assist makers in streamlining operations and improving product longevity.

Contact us today to learn how our foam solutions can elevate your upholstery production.